To ensure the safety of the active substances in medicinal products, photostability tests should be carried out as these are subject to high safety standards before they are placed on the market.

Through security controls, established by the pharmaceutical industry, they are an essential part of the authorization and registration of a product, since no product can be planned without having passed the stability study. The main purpose of these tests is to certify the storage of pharmaceutical products under certain storage conditions.

In this sense, photostability tests, through good manufacturing practices, are checked for resistance to light and temperature, are as homogeneous as possible, to confirm that they do not vary impermissible.

Conduct of Tests

In essence, photostability tests are used to test the resistance to light of new active substances and medicines, and to test this, tests must be carried out efficiently, where the main priority is to make light conditions and temperature as similar as possible.

The tests are also performed to check the intrinsic stability of the molecule, by incorporating degradation patterns and validation of stability, indicating how appropriate the analytical procedures are used. Similarly, these tests assess the stability of a product to light radiation, the source of which can be direct sunlight or artificial light.

It is recommended that a systematic approach to photostability studies should cover, as appropriate, studies such as:

- Studies on the active substance

- Studies of exposed drugs outside the immediate packaging.

- Drug studies in immediate conditioning.

- Drug studies on commercial containers.

Through these studies, application is due to testing and outreach for the evaluation and verification of changes in medicinal products, and corroborate acceptance or rejection of testing factors.

Factors Involved in Testing

Through the development of photostability tests, necessary factors such as light sources and temperature are involved and to minimize the effect of localized changes, verification controls are included.

For such tests, it is based on the spectral distribution specification of light standards, which are:

- D65/ID65 standard, such as an artificial fluorescent daylight lamp combining visible and ultraviolet (UV) radiation, xenon lamp or metal halide lamp.

- D65 is the internationally recognized standard for outdoor daylight.

- ID65 is the equivalent indirect indoor daylight standard. For a light source that emits significant radiation below 320nm, an appropriate filter(s) can be adapted to eliminate such radiation.

Accordingly, for confirmatory studies, samples should be exposed to light, providing an overall illumination of not less than 1,2 million lux-hours and an integrated near ultraviolet energy of not less than 200 watt hours/square meter, in order to allow direct comparisons between the active substance and the medicinal product.

The confirmatory studies shall be resumed at a later stage in order to provide the information necessary for handling, packaging and labeling.

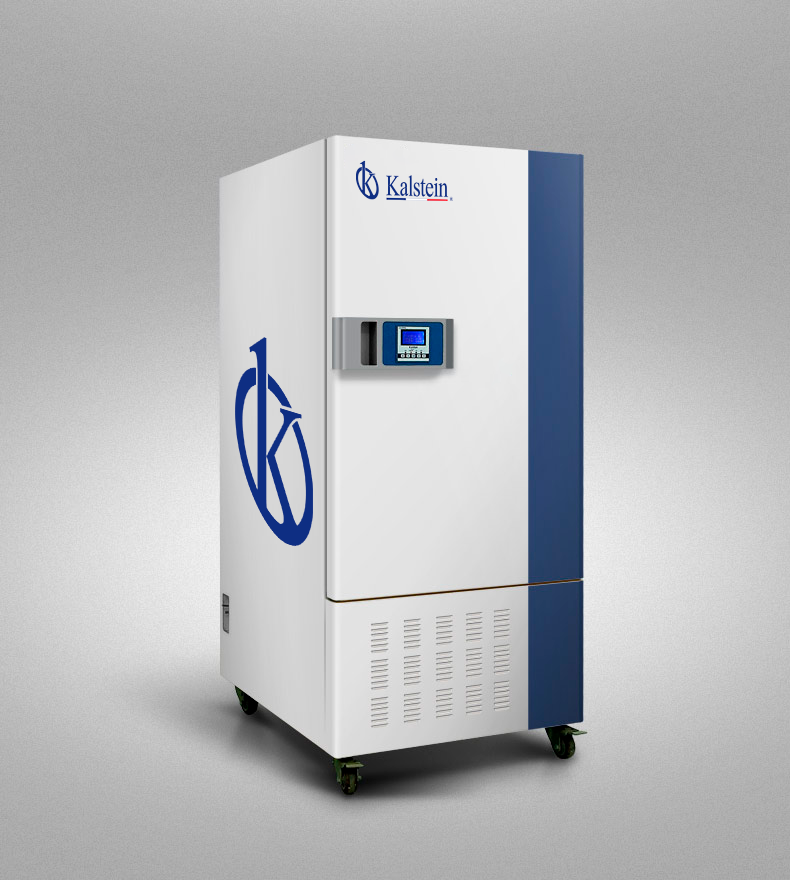

Kalstein brand drug stability testing chamber

At Kalstein, we are trained to offer you the best medical equipment, capable of meeting all the demands of our clients. We provide you with the best technology, as is the case of the comprehensive drug testing chambers of the YR model, which provides all the benefits for the preservation of medicines. For this reason, our medical team has attractive features, such as: LCD screen with integrated dot matrix, Chinese and English subtitles, designed for maximum operational comfort. Display parameters: temperature, humidity, cycle, run time, run time and stop. The adaptive PID controller precisely controls temperature and humidity, prevents temperature from rising, keeps ambient temperature stable and uniform. Programmable multi-section control, to meet customer needs, temperature and humidity control up to 30 sets. Time setting: 0-99h, 0-9999m, programs can be run automatically in cycles. Set up operations with beep tips. Remote control of computer software, professional operation Software ALLSENSTM (optional). HERE

For more information, check out HERE