Viscometer

A viscosimeter is an essential instrument in any laboratory setting, particularly in industries such as pharmaceuticals, food processing, and cosmetics, where the viscosity of liquids plays a crucial role in product quality. By accurately measuring the viscosity of substances, a viscosimeter helps ensure consistency in production processes, adherence to quality standards, and compliance with regulations. At Kalstein, we understand the importance of reliable and precise viscosimeters in laboratory operations, which is why we offer a wide range of advanced viscosimetry equipment to meet varying needs.

Our selection of viscosimeters includes rotational viscometers, falling ball viscometers, and capillary viscometers, among others, designed to provide accurate viscosity measurements for a diverse range of applications. Whether you need to test the flow properties of fluids, monitor consistency during manufacturing processes, or conduct research and development activities, our high-quality viscosimeters deliver dependable results to support your lab’s objectives. Trust Kalstein for all your laboratory equipment needs, and elevate your viscosity testing capabilities with our cutting-edge viscosimetry solutions.

VISCOMETER KALSTEIN

At Kalstein you can find the ideal Viscometer for Your Laboratory

Small Sample Viscometer YR05865

The digital rotary viscometer adopts coaxial cylinder structure, using small sample adapter, the sample quantity required for each measurement is very small, ...

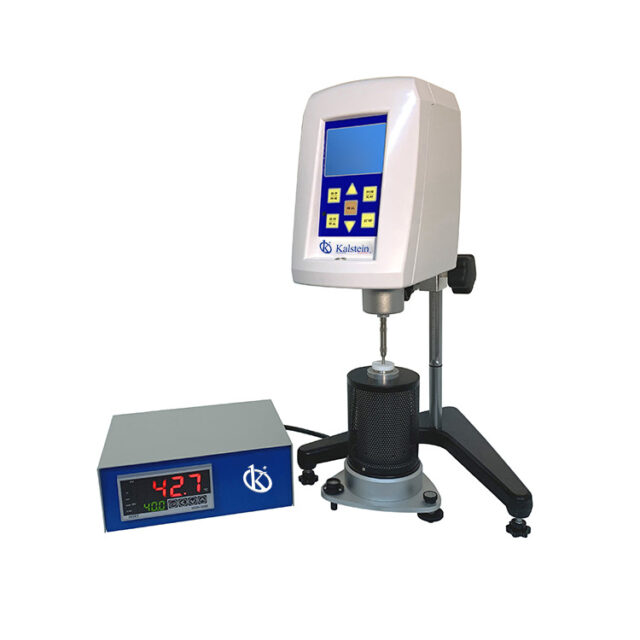

Cosmetics Rotating Dial Viscometer YR05851 – YR05852

Test the viscosity of Newtonian and non-Newtonian liquids No. 0 Spindles can test 1-10 mpa.s. Attachments: No. 1,2,3,4 Spindles No. 0 Spindles is ...

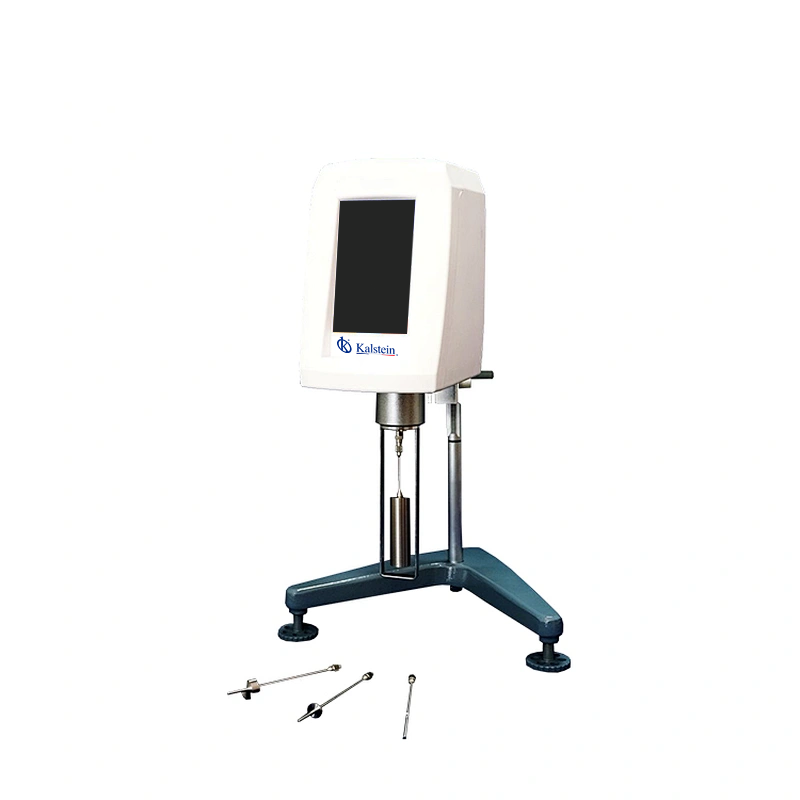

Lab Rotational Viscometer YR05853 – YR05854

Test range from 1 to 100,000 mpa.s (cps) High accuracy Automatic detection Easy to operate Attachments: No. 1,2,3,4 Spindles No. 0 Spindle Adapter Prot...

Touch Screen Brookfield Viscometer YR05858 – YR05859

Perfect integration of touch-screen technology, fast, accurate, easy to measure viscosity. Step-less debugging, can measure super high viscosity of the sample. 5-in...

Our Viscometer best seller

The perfect integration of touch screen technology, high technology in a modern fashion to fast, accurate and convenient measurement of paint, paint or ink viscosity. 5 inch color touch screen full, vivid display of various parameters and work conditions. With rich content, convenient operation, high measure accuracy, good repeatability, stable speed, obvious advantages of strong anti-jamming performance. Widely used to determine the paint, ink, paint or other KU values to represent the viscosity of the industry, in line with international standards ASTM, D562 And GB9296 and other related standards.

Features

The operation interface is simple and clear, the viscosity test can be done quickly and conveniently through the creation of test program and data analysis;

Accurate: automatic calibration by computer, high precision, small error;

Rich display: in addition to KU, G, CP of the three commonly used parameters, and temperature measurements for the full-scale value percentage (graphics), viscosity curve, range overflow alarm, timing, clock date, etc

| Model | YR05857 |

| Speed(r/min) | 200±0.1 |

| Measuring range | 40.2KU – 141.0KU 32g – 1099g 27 – 5250CP |

| Measurement accuracy | ±3% |

| measurement reproducibility | ±1.5% |

| Measuring container | 1 pint |

| Save the measurement results | 30 sets of data (including KU, G, cP, time, curves, etc.) can be saved |

| Viscograph | Real time display viscosity curve |

| Power supply | 110V / 60Hz or 220V / 50Hz |

| Dimension | 350 * 350 * 450(mm) |

Analysis of the best Viscometer for Your Laboratory

A Deep Dive into Innovations in Digital Viscometers

Countless improvements in technology have revolutionized the way laboratory tests are conducted. As a leading manufacturer of laboratory equipment, Kalstein prides itse...

The crucial role of viscometers in industry

The crucial role of viscometers in industry is unquestionable. They are used to measure viscosity-related properties such as flow resistance, resistance to deformation f...

The different types of viscometers

Viscometers are very useful tools that are used in a variety of industries and applications. These tools are used to measure the viscosity of liquid and fluid product...

The viscometer: Observing pathological anatomy with it

A viscometer is a mechanical measuring device used to measure viscosity, the resistance of a fluid to flow; these devices are often used to evaluate the state ...

Catalog of models of Viscometer on offer

Cosmetics Rotating Dial Viscometer YR05851 – YR05852

Select options

Lab Rotational Viscometer YR05853 – YR05854

Select options

Viscosity Measuring Analyzer Laboratory Viscometer YR05855 – YR05856

Select options

Stormer Viscometer YR05857

Add to cart

Touch Screen Brookfield Viscometer YR05858 – YR05859

Select options

Brookfield Viscosity Tester YR05860 // YR05864

Select options

Small Sample Viscometer YR05865

Add to cart

Digital Small Sample Viscometer YR05840 // YR05842

Select options

KALSTEIN UPDATED

Guidelines for you to become an expert in Viscometer

The Viscometer equipment are essential products in Your Laboratory, we provide you with guidance and recommendations for a better use, so you can work like an expert.

How does the Viscometer work?

How is the Viscosity of Motor Oil measured?

Perfecting Fluid Analysis: How the Viscosity Meter

The basic principles of viscometers

Frequently asked questions from our customers about Viscometer

The delivery time of your Kalstein product will depend on the following:

- Whether the equipment you are interested in is in stock or if it needs to be manufactured.

- The type of freight you have chosen, which can be either air or sea.

- Equipment in stock:

– Delivery Time (Air): 15-30 days.

– Delivery Time (Sea): 45-60 days.

- Equipment not in stock:

– Delivery Time (Air): 30-60 days.

– Delivery Time (Sea): 60-90 days.

You can make your purchase through:

- By email: [email protected]

- By phone: +33 (0) 1 70 39 26 50

- Online shopping: Through the official Kalstein website in your country.

At Kalstein, we provide our customers with inductions and technical support through new online methods. You can visit our induction videos, technical assistance, and guidance provided by a Kalstein team through our Youtube channel (Kalstein English). HERE

Send us a direct message and one of our agents will contact you

Viscometer

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed dignissim placerat mauris cursus laoreet. Nam feugiat lacus ex, at fermentum sapien accumsan nec. Curabitur auctor porttitor mi non malesuada. Aenean condimentum, purus vitae rhoncus imperdiet, justo eros aliquam ipsum, at egestas leo diam eget libero.

Catalog of models of Viscometer on offer.

-

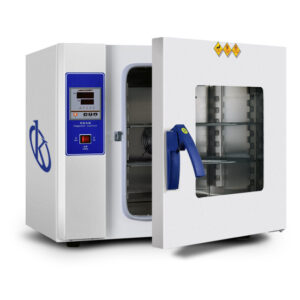

Electric Heating Drying Oven YR06446

-

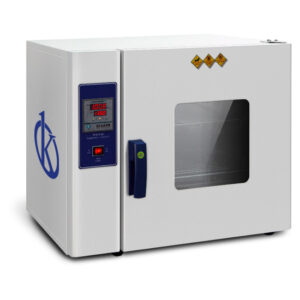

Electric Heating Drying Oven YR05259-2

-

Electric heating drying oven YR05248 // YR05255

This product has multiple variants. The options may be chosen on the product page -

Electric heating drying oven YR05244 // YR05247

This product has multiple variants. The options may be chosen on the product page -

Mini Centrifuge With Large Capacity YR012G

-

Tabletop High Speed Centrifuge YR0137-2 – YR0137-3

This product has multiple variants. The options may be chosen on the product page -

Gel Card Centrifuge YR142-3 – YR142-3-1

This product has multiple variants. The options may be chosen on the product page -

Tabletop High Speed Centrifuge YR019-TG

This product has multiple variants. The options may be chosen on the product page -

Intelligent Electric Wheelchair YR06432

-

Electric Wheelchair YR05445

-

Electric Wheelchair YR05443

-

Electric Wheelchair YR05442

-

Electric Wheelchair YR05444

-

Electric Wheelchair YR05441

-

Electric Wheelchair YR05440

-

Electric Wheelchair YR05439

Descubre más de nuestro catálogo

Tipos de Viscometer

[Producto] A

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

[Producto] B

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Find out more about Viscometer with our guides.

Incubators: Reliable Thermal Control for Cell and Microbial Cultures

In the world of scientific research and laboratories, having precise equipment is key to obtaining reliable and reproducible results. Incubators...

Essential Technology for Genetic and Protein Analysis

Electrophoresis has become an indispensable tool for laboratories looking to conduct genetic and protein analyses with precision and efficiency. If...

Analyzers: Versatile Solutions for Sample Evaluation in Laboratories

In the realm of scientific research and quality control, analyzers have become essential tools for the precise and rapid evaluation...