A homogenizer is a laboratory equipment that is used to carry out the homogenization process of different types of materials; such as tissues, food, plants and other biological or chemical elements. In laboratories, homogenization is generally a necessary step in the preparation of biological samples in laboratories, among them we can mention before the analysis of nucleic acids and proteins, or the study of cells, metabolism, bacteria, fungi, parasites and viruses. as well as in other scientific purposes.

Today there are many models of laboratory homogenizers on the market. At Kalstein we are specialists in the manufacture of laboratory equipment and below we will show you different models, tips and information so that you can choose the homogenizer that best suits your needs and the activities you carry out in your laboratory.

Types of homogenizers according to your disposition

- Portable Homogenizer (handheld homogenizer): They present rotary movements, they are used at speeds that oscillate between Min: 5000 rpm and Max: 35000 rpm. Available models typically use polycarbonate or stainless steel test leads. It is the most ideal if you want to move from one place to another to carry out tests, they have a good level of homogenization due to the high speed motor and it has high torque.

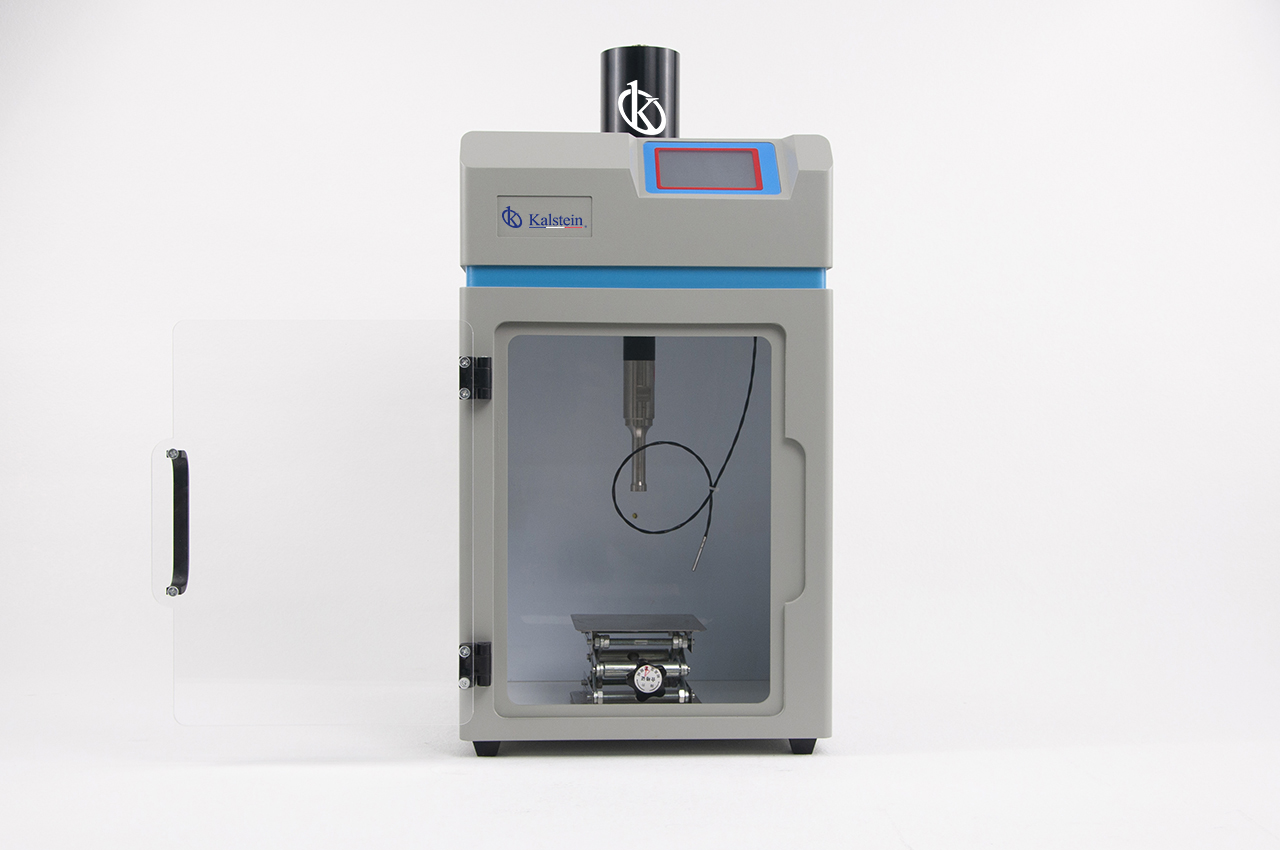

- Floor Homogenizer: They are large, they can use fluidized bed technology, rotors and stators or ultrasound. If you have enough space in your laboratory and you have regular work that requires high-power equipment, it is the most suitable for you.

- Tabletop Homogenizer: These homogenizers have a rotary movement, have versatility for use, are ideal for emulsifying, mixing and grinding different types of samples, they work at different speeds. They come in a variety of sizes and capacities.

Homogenizers according to the manufacturing technique

- Ultrasound homogenizer: They allow a mechanical process in which the particles in a liquid are reduced, in order to obtain uniformity in their size and distribution. It is the most suitable and effective when it is necessary to dissolve cells and subcellular structures in a fluid mixture. It works by releasing extreme waves of suspended sound pressure. Ultrasound waves and cavitation act on cells and tissues, but not on intact tissues. It works by forming tiny bubbles in the liquid due to flow caused by pressure waves, and cavitation occurs when these bubbles grow and converge to maximum size, shake vigorously, and then collapse.

- Pressure homogenizer: This type of homogenizer works with a high pressure valve. They act by forcing suspensions through a conical opening or by opening them under considerable pressure thus creating a homogeneous suspension. It uses a technique capable of destroying cells, bacteria and yeast.

- Rotor-stator homogenizer (mechanical): They have a system designed to achieve perfect homogenization due to a rotor with bladed blades that rotates in a stationary state at high speed, having holes through which the fluid moves. In many cases it offers multiphase configurations of rotors and stators and special ultra-fine meshes that provide high intense shear, further reducing homogenization times by reducing the number of recirculation steps required. Using this type of agitators the blade (rotor) acts as an agitator for the solid sample through the liquid at the speed required for the cavitation process to occur, which is nothing more than the formation of vapor cavities in a liquid that is stirred by a specific propeller.

- Fluidized bed homogenizer: It is a type of homogenizer that uses a process in which an ascending stream of fluid suspends the solid particles.

At Kalstein we are MANUFACTURERS of laboratory equipment and we have an excellent range of laboratory homogenizers at the best PRICES on the market. That is why we invite you to take a look at the Products menu. HERE